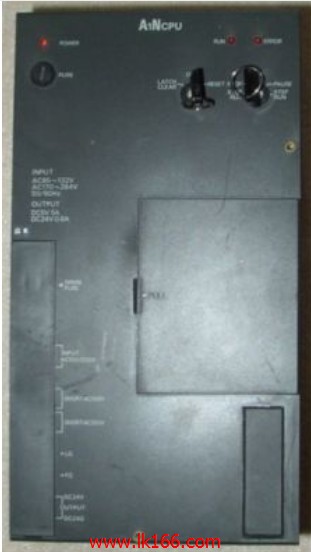

A1NCPU CPU unit MITSUBISHI A1NCPU

2 channels.

200/10kpps.

Count input signal: RS-422-A (gap dynamic appearance of rye).

External input: RS-422-A (gap dynamic appearance rye).

Compare output: transistor DC12/24V, 0.5A/1 point, 2A/1 common.

20 point terminal station.

Structured text language is a programming language that describes a program with a structured description of the text A1NCPU.

Structured text is often used to describe the relationship between the various variables in the control system based on the PLC system A1NCPU.

Mainly used for other programming languages more difficult to achieve the user program.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions A1NCPU.

Each step represents a control function, represented by the box MITSUBISHI A1NCPU.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions MITSUBISHI A1NCPU.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced MITSUBISHI A1NCPU. PLC station distance: 1Km.

Cable type: QSI-200/250.

The function of the MELSECNET interface module is to connect the main CPU PLC to the MELSECNET data communication system.

As long as the switch on the component to set, you can determine the CPU PLC is as a main station or in situ station.

There are two modules available for selection: one is the connection of the optical cable network and the network of the coaxial cable.

For a ANSCPU, up to only a piece of interface components can be inserted, A2ASCPU can be inserted 2.

The popularization and application of PLC programming has been developed rapidly in our country,

It has been widely used in all kinds of mechanical equipment and production process of electrical control devices,

All walks of life have emerged a large number of application of PLC transformation of the results of the equipment.

Understand the working principle of PLC, have the ability to design, debug and maintain the PLC control system,

Has become the basic requirements of modern industry for electrical technicians and engineering students.

The instruction list programming language is a programming language similar to assembly language mnemonic,

As well as assembly language by the operation code and the number of operations.

In the case of the computer for the PLC handheld programmer compile user program.

At the same time, the programming language of the instruction list corresponds to the ladder diagram programming language,

In PLC programming software can be converted to each other. Figure 3 is the instruction sheet corresponding to the ladder diagram of figure 2PLC.

The characteristics of instruction table programming language is used to represent mnemonic operation function,

Easy to remember, easy to grasp;

In the handheld programmer on the keyboard using the mnemonic representation, easy to operate, can be programmed in computer;

There is a one-to-one correspondence between the ladder diagram and the ladder diagram. Its characteristics are basically consistent with the ladder diagram language.

Input and output points: 256 points.

Input / output data points: 256 points.

Program capacity: 6k.

Basic command processing speed (LD command) s:1.0.

Internal storage RAM memory capacity: 16k.

User program storage capacity: it is a measure of how much the user application can store the number of indicators.

Usually in words or K words as units. 16 bit binary number is a word,

Every 1024 words are 1K words. PLC to store instructions and data in words.

General logical operation instructions each account for 1 words. Timer / counter,

Shift instruction accounted for 2 words. Data operation instructions for 2~4.

Integral type: the PLC components are installed together or a few pieces of printed circuit board,

And together with the power supply iinstalled in the casing to form a single overall called the host or the basic unit, small, ultra small PLC using this structure A1NCPU.

Modular: PLC is the basic components of a separate module.

Medium and large PLC used this way. Easy maintenance.