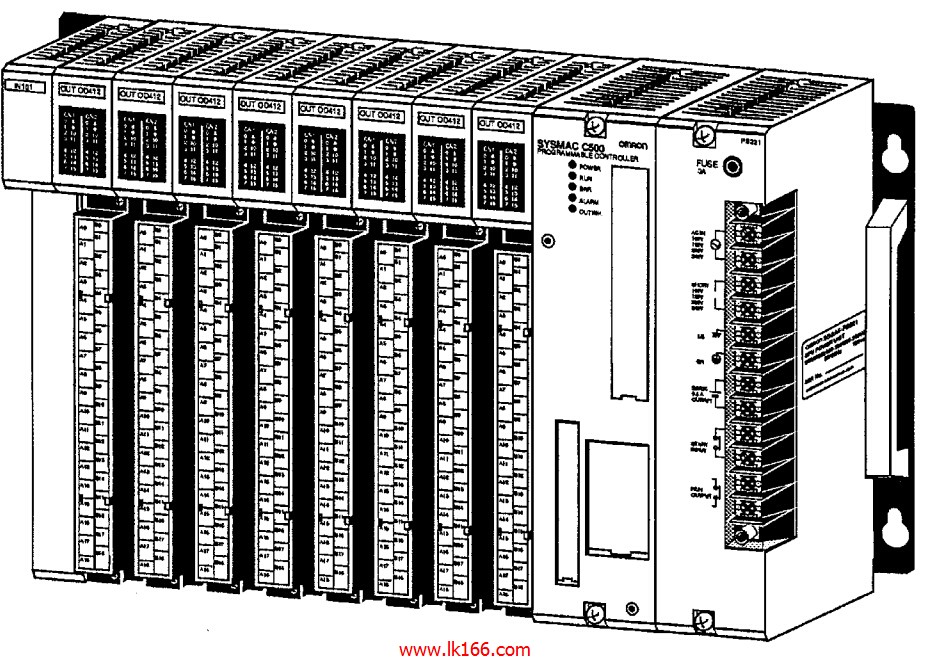

C500-OD218 OMRON C500-OD218

I/O Cable (for I/O to Interface Racks) 2 m (L) CV500-CN222Type: CJ1 Special I/O Unit.

Connected ID System: V680 Series; 1 Head.

External power supply: --.

No. of unit numbers used: 1 unit number.

Current consumption: 5V, 0.26A;

24V, 0.13A; External, --.

Communication Unit Dedicated for RFID V680,

Allowing Direct Connection to OMRON PLC CJ/

CS/NJ-series C500-OD218.

Communication unit for connecting RFID V680-series,

which can be used around the world, directly to PLC C500-OD218.

Allows batch transfer of data up to 32 kbytes.

C500-OD I/O Unit Transistor Output 32 pts C500-OD218.

DC12~24V 0.3A.Expands G730 input capacity of G730 remote master;

adds 32 or 16 inputs,

DIP switch selected.Name: Position Control Module.

Model: C200HW-NC113 C500-OD218.

Control method: Open-loop, automatic trapezoid acceleration/deceleration.

Control output sig-nals: Pulse-train outputs.

Controlled axes: 1.Name: CS1D CPU Backplane.

Specifications: Applicable systems,

Duplex CPU, Dual I/O Expansion System only;

Number of Power Supply Units,

2 Units max OMRON C500-OD218. (for duplex operation);

Number of I/O Units, 5 Units max.

(including the I/O Control Units).

Current consumption: 5V system, 1.20A;

26V system, --.

Standards: UC1, CE.

Redundant CPU Units , Power Supply Units ,

Communications Units ,

and Expansion I/O Cables OMRON C500-OD218.Unit type: CS1 Special I/O Units.

Product name: Isolated-type,

Resistance Thermocouple Input Units.

points Input: 4 inputs.

Signal range selection:

Set separately for each input.

I/O type: Pt100, JPt100.

Conversion speed (resolution):

100 ms/4 inputs OMRON C500-OD218.

Externa connection: Removable erminal block.

No. of unit numbers allocated: 1.

Current consumption: 5V, 0.15A; 26V, 0.15A.

Standards: UC1, CE.

Provides the functionality of isolators,

power supplies, signal converters,

and other devices.

The Analog Input Unit converts analog,

input signals such as 1 to 5 V or 4 to 20mA,

into digital values, and takes the values,

scaled in industrial units, and transfers,

it to the CPU Unit as the process value.

Because of this, no ladder program is required,

at the CPU Unit for scaling.

The Analog Output Unit converts analog output set,

values from the CPU Unit to analog output signals,

such as 4 to 20 mA or 1 to 5 V, and outputs them.

The built-in functions, such as measurement value,

alarms, rate-of-change calculations, and square roots,

have enabled major savings in cost and space compared,

with previous systems.

High-resolution Models and 8-point Input Models are,

also available.

By combining the Units, logging/monitoring. <

systems can be constructed,

or the Units can be used together with LCBs/LCUs,

to construct complete process control systems C500-OD218.

Parameters can be easily displayed and set in an,

easy-to-understand form without special tools.